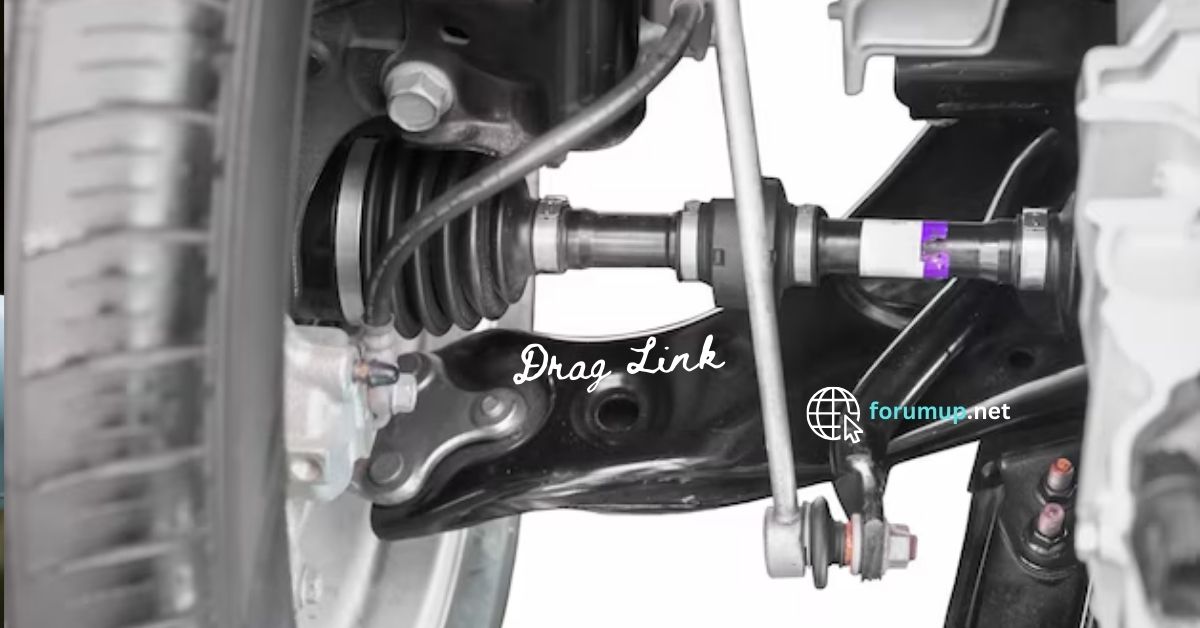

The drag link is a vital part of a vehicle’s steering system, ensuring accurate control and stability. Found in many trucks, SUVs, and heavy-duty vehicles, this component connects the steering gearbox to the steering knuckles, translating the driver’s input into precise wheel movement. Let’s explore its function, design, and importance in maintaining vehicle safety.

What Is a Drag Link?

The it is a mechanical rod that transfers the rotational movement of the steering wheel to the front wheels of the vehicle. It works as part of a larger steering linkage system, complementing components like tie rods and the pitman arm.

How a Drag Link Works

Connection: The it connects the pitman arm (attached to the steering gearbox) to the steering arm or knuckle.

Movement Translation: When the steering wheel turns, the it moves laterally, transferring force to steer the wheels in the desired direction.

Ensuring Alignment: It helps maintain the correct alignment and synchronization between the left and right wheels.

Types of Drag Links

Solid Drag Links: A single piece of metal, often used in heavy-duty vehicles for durability.

Adjustable D,rag Links: Equipped with threaded ends for fine-tuning alignment, commonly found in modern vehicles.

Common Materials Used

Its are typically made from high-strength materials like steel or aluminum to withstand the stress and load of steering forces.

Signs of a Failing Drag Link

A worn or damaged it can compromise vehicle safety. Watch for these signs:

Loose Steering: Difficulty maintaining control or excessive play in the steering wheel.

Uneven Tire Wear: Misaligned wheels caused by an ineffective it.

Noisy Steering: Clunking or rattling sounds when turning the wheel.

Vehicle Pulling: The car veering to one side despite straight steering.

Causes of Drag Link Failure

Wear and Tear: Prolonged use leads to joint or rod degradation.

Corrosion: Exposure to moisture and road salt can weaken the metal.

Overloading: Excessive weight or strain on the steering system accelerates damage.

How to Inspect and Maintain a Drag Link

Visual Inspection: Look for bends, cracks, or rust on the drag lin,k.

Joint Testing: Check for excessive play or looseness in the connections.

Alignment Check: Ensure the wheels are properly aligned, as misalignment may indicate its issues.

Replacing a Drag Link

If it is damaged beyond repair, it should be replaced immediately. The process involves:

Lifting the vehicle and removing the wheels for access.

Detaching the old it from the pitman arm and steering knuckles.

Installing the new it and securing it with bolts.

Performing a wheel alignment to ensure proper steering performance.

Importance of a Functional Drag Link

A healthy drag lin,k ensures:

Accurate Steering: Precision in wheel movement.

Safety: Prevents loss of control during driving.

Even Tire Wear: Prolongs tire life by maintaining alignment.

Conclusion

It may not be the most talked-about vehicle component, but its role in steering systems is irreplaceable. Regular maintenance and timely replacement of a worn it are crucial for a safe and smooth driving experience.

FAQs

1. What happens if a drag link fails?

A failing it can cause loose steering, misalignment, and a loss of control, posing a significant safety risk.

2. How long does a drag link last?

The lifespan depends on driving conditions, but most its last between 80,000 and 100,000 miles.

3. Can I drive with a damaged drag link?

Driving with a damaged it is unsafe and should be avoided. Immediate repairs or replacement are necessary.

4. Is it the same as a tie rod?

No, while both are part of the steering system, it connects the pitman arm to the steering knuckle, whereas tie rods link the steering rack to the wheels.

5. How much does it cost to replace a drag lin,k?

Replacement costs range from $200 to $500, depending on the vehicle and labor charges.